Solar Panel Maintenance Using Thermal Drone Inspection

In the realm of renewable energy, the maintenance and upkeep of solar panels are critical to ensuring their efficiency and longevity. Traditional methods of inspection often involve labor-intensive processes that are time-consuming and may pose safety risks to maintenance personnel. However, with advancements in technology, particularly in the realm of thermal drone inspection, the landscape of solar panel maintenance is rapidly evolving. Thermal drones equipped with infrared cameras offer a revolutionary approach by enabling swift, comprehensive, and non-intrusive inspections of solar panel arrays. This method not only enhances the efficiency and accuracy of diagnostics but also reduces operational costs and minimizes downtime. By harnessing the power of these advanced aerial tools, the solar energy industry is poised to achieve higher levels of reliability and performance while supporting sustainable energy practices. This introduction explores the transformative impact of thermal drone inspection in solar panel maintenance, highlighting its benefits and the future potential in optimizing renewable energy infrastructure.

Challenges in Solar Panel Maintenance

Solar panel maintenance is essential to ensure optimal performance and longevity of the system. However, it comes with several challenges and problems that need to be addressed. Here are some of the main issues:

Environmental Factors

- Weather Conditions: Dust, dirt, bird droppings, pollen, and other debris can accumulate on panels, reducing their efficiency. Harsh weather conditions like hail, heavy snow, and storms can cause physical damage.

- Shade and Vegetation: Over time, growing vegetation or newly constructed buildings can cast shadows on panels, reducing their efficiency. Keeping the area around the panels clear can be challenging.

Mechanical and Electrical Issues

- Wear and Tear: Components like inverters, wiring, and connectors can degrade over time, leading to potential system failures.

- Panel Degradation: Solar panels naturally degrade over time, losing efficiency. Identifying and replacing degraded panels can be a logistical challenge.

- Hot Spots: Localized heating of panels can lead to hot spots, which can damage the panels and reduce their lifespan.

Monitoring and Diagnostics

- Lack of Real-Time Monitoring: Without a real-time monitoring system, identifying performance issues promptly can be difficult.

- Complex Diagnostics: Diagnosing problems can require sophisticated equipment and expertise, particularly for issues that aren’t immediately visible.

Maintenance Accessibility

- Difficult-to-Access Installations: Roof-mounted panels or panels in remote locations can be difficult and dangerous to access for cleaning and repairs.

- Large Scale Systems: For large solar farms, inspecting and maintaining each panel is time-consuming and labor-intensive.

Disadvantages of Traditional Methods

Here are four major disadvantages of traditional methods in solar panel plant maintenance:

Labor-Intensive and Time-Consuming

Traditional methods of solar panel maintenance are highly labor-intensive and time-consuming. Technicians must physically inspect each panel, a process that can be extremely slow, especially for large solar farms. This not only results in high labor costs but also diverts resources away from other critical tasks. The time required for manual inspections can lead to delayed identification of issues, further affecting the overall efficiency of the solar panel system.

Safety Risks

Manual inspection and maintenance of solar panels pose significant safety risks. Technicians often have to work at heights, navigate difficult terrains, and deal with high voltage electrical components. This increases the risk of falls, electrical shocks, and other injuries. Ensuring the safety of maintenance personnel requires strict adherence to safety protocols and the use of specialized equipment, which can further complicate and prolong the maintenance process.

Inefficiency in Detecting Issues

Human error is a significant drawback of traditional inspection methods. Manual inspections are prone to mistakes, leading to missed issues or incorrect diagnoses. Additionally, these inspections typically only identify surface-level problems, while underlying issues that could affect the panels’ performance may go undetected. This inefficiency in detecting problems promptly can result in prolonged periods of reduced efficiency and higher repair costs in the long run.

Limited Accessibility and Scalability

Traditional maintenance methods struggle with accessibility and scalability. Solar panels located in remote or hard-to-reach areas are difficult to inspect regularly. Rooftop installations present additional challenges, requiring specialized equipment and increasing the risk of accidents. As solar farms grow in size, these limitations become more pronounced, making it difficult to maintain efficiency and thoroughness in inspections. Scaling up traditional maintenance methods to accommodate large installations is resource-intensive and often impractical.

Advantages of Drone Technology

Advantages of Drone Inspection Technology in Solar Panel Plant Maintenance

-

Efficiency and Speed:

Drone inspections can cover large areas quickly and efficiently, significantly reducing the time required for inspecting solar panels. With drones, a task that would take days or weeks using traditional methods can be completed in a matter of hours. This increased speed allows for more frequent inspections, ensuring that issues are detected and addressed promptly.

-

Enhanced Safety:

Using drones for solar panel inspections eliminates the need for technicians to climb on rooftops or navigate through difficult terrain, reducing the risk of falls and injuries. Drones can safely inspect panels from a distance, capturing detailed images and thermal data without putting human inspectors in harm’s way. This leads to a safer working environment and lowers the risk of accidents.

-

Comprehensive Data Collection:

Drones equipped with high-resolution cameras and thermal imaging sensors can collect detailed data on the condition of solar panels. This technology can identify hot spots, cracks, dirt accumulation, and other issues that may not be visible to the naked eye. The comprehensive data collected by drones allows for precise diagnostics and targeted maintenance, improving the overall efficiency of the solar panel system.

-

Cost-Effectiveness:

Although the initial investment in drone technology can be significant, it can lead to substantial cost savings in the long run. By reducing the need for manual labor, transportation, and specialized equipment, drones can lower operational costs. Additionally, early detection of issues through regular drone inspections can prevent costly repairs and replacements, further enhancing the cost-effectiveness of maintenance activities.

-

Improved Accessibility:

Drones can easily access hard-to-reach areas, such as rooftop installations and remote solar farms. This capability ensures that all panels, regardless of their location, receive regular inspections. Improved accessibility also means that maintenance can be performed more consistently and thoroughly, enhancing the overall performance and longevity of the solar panel system.

-

Real-Time Monitoring and Reporting:

Drone technology enables real-time monitoring and reporting of solar panel conditions. The data collected can be transmitted instantly to a central system, allowing for immediate analysis and decision-making. Real-time reporting ensures that any detected issues are addressed promptly, minimizing downtime and maintaining optimal efficiency.

-

Scalability:

Drone inspections are highly scalable, making them suitable for solar installations of all sizes. Whether inspecting a small residential array or a large solar farm, drones can efficiently handle the task. This scalability allows for consistent maintenance practices across different installations, ensuring that all systems operate at peak efficiency.

-

Environmental Benefits:

Drone inspections reduce the need for manual interventions, which often involve transportation and the use of resources. By minimizing the environmental footprint of maintenance activities, drones contribute to the overall sustainability of solar energy systems. Additionally, maintaining optimal performance of solar panels through regular drone inspections ensures maximum energy production, supporting renewable energy goals.

The future of drone inspections in the solar industry is promising, with advancements in AI and machine learning paving the way for even more intelligent systems. Future drones will not only capture thermal data but also analyze it in real-time, pinpointing issues with unprecedented accuracy. According to U.S. EIA, there are more than 2.500 utility-scale solar farms in the US alone. As with any other infrastructure, regular inspection and maintenance becomes a cumbersome task for such vast areas. Investing in AI drone technology for solar farm inspection is transforming the industry by improving efficiency and reducing costs. The market potential for AI drone solar farm inspection is substantial, driven by the need for efficient defect detection. By utilizing advanced imaging technologies and AI algorithms, these drones can swiftly detect defects, malfunctions, and areas of inefficiency in solar panels. This efficient defect detection not only reduces costs but also leads to improved maintenance practices. Companies investing in AI drone technology aim to enhance operational efficiency, gaining a competitive edge in the market.

How Thermal Drone Inspection encountering the challanges in solar plant maintenance?

Thermal drone inspection technology is revolutionizing the maintenance of solar plants by effectively addressing several key challenges. One of the primary issues in traditional solar panel maintenance is the inefficiency in detecting and diagnosing problems, often resulting in missed or delayed identification of issues. Thermal drones equipped with high-resolution infrared cameras can quickly and accurately identify hot spots, cracks, and other defects that are invisible to the naked eye. This allows for precise and timely interventions, preventing minor issues from escalating into major problems. Additionally, the ability of drones to access hard-to-reach areas, such as rooftop installations and expansive solar farms, significantly improves the comprehensiveness of inspections. This eliminates the safety risks associated with manual inspections, such as falls and electrical hazards, ensuring a safer working environment for maintenance personnel. Furthermore, thermal drones provide real-time data collection and analysis, enabling proactive maintenance strategies and reducing the downtime of solar panels. By integrating advanced data analytics, thermal drone inspections facilitate predictive maintenance, optimizing the performance and longevity of solar installations while reducing operational costs and enhancing overall efficiency.

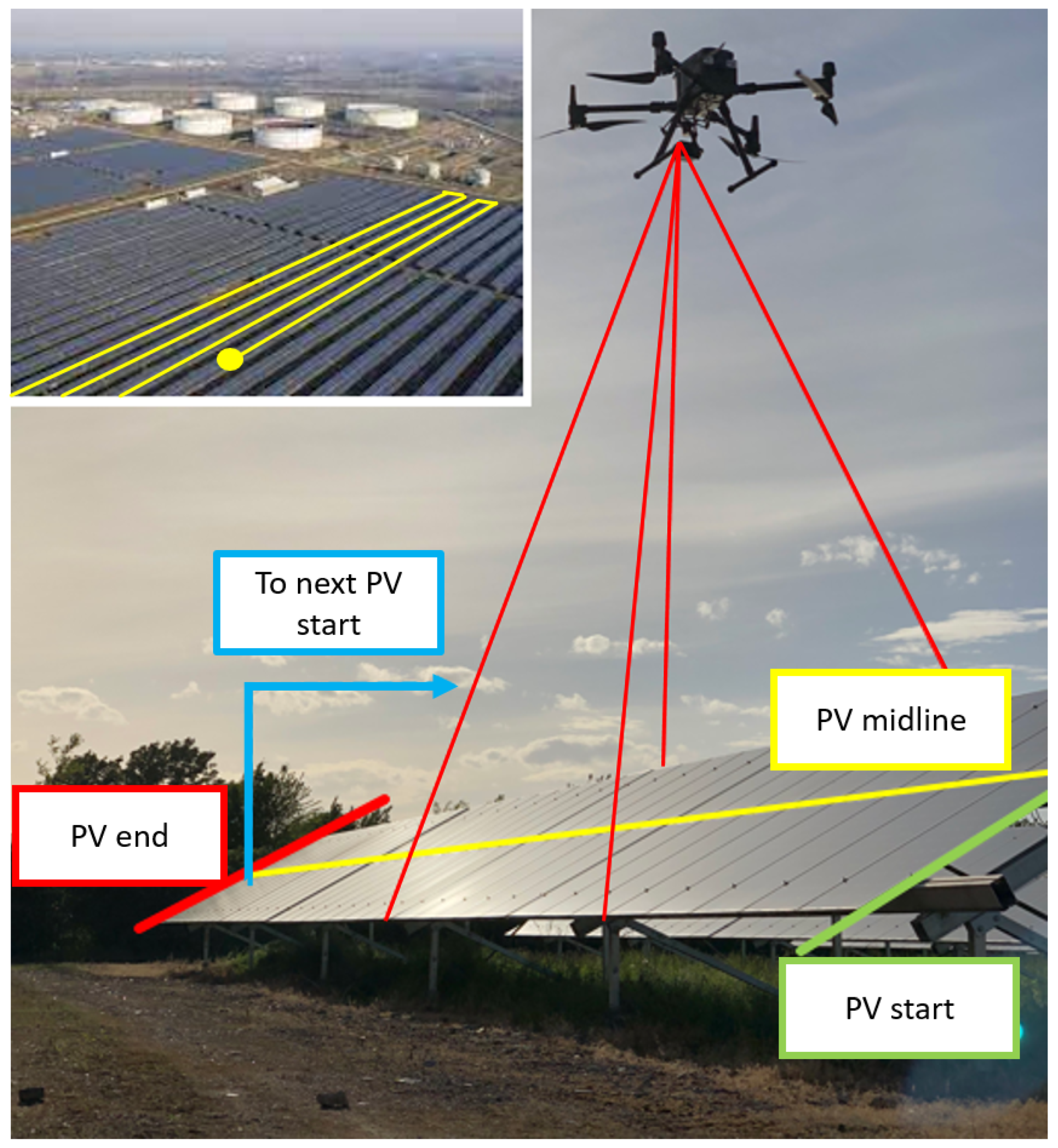

Computer Vision-Based Solution

A computer vision-based solution for thermal drone inspection in solar plant maintenance leverages advanced algorithms and sensors to enhance the efficiency and accuracy of monitoring solar panel conditions. This technology utilizes thermal imaging cameras mounted on drones to capture detailed heat signatures from solar panels, identifying potential issues like hot spots, faulty cells, or debris accumulation. Computer vision algorithms analyze these thermal images in real-time, detecting anomalies and generating actionable insights for maintenance teams. By automating the detection process, this solution reduces reliance on manual inspections, thereby minimizing human error and ensuring consistent, thorough assessments across large-scale solar farms. Moreover, the integration of computer vision allows for predictive maintenance strategies, where data trends over time can predict future failures or performance degradation, optimizing maintenance schedules and maximizing energy production efficiency. Overall, computer vision-based solutions for thermal drone inspection represent a significant advancement in solar plant maintenance, offering improved reliability, safety, and cost-effectiveness in managing renewable energy assets.

Conclusion

Thermal drone inspections represent a significant leap forward in solar panel maintenance. By embracing this cutting-edge technology, the solar industry can achieve higher efficiency, lower costs, and enhanced safety. The ability to conduct thorough, real-time inspections without disrupting operations positions thermal drones as an indispensable tool in the pursuit of sustainable energy. The integration of thermal drone inspection technology in solar panel maintenance represents a transformative leap forward in optimizing the performance and longevity of solar energy systems. By harnessing the power of advanced AI-driven algorithms and drone capabilities, this approach offers numerous benefits. Firstly, thermal drones enable swift and comprehensive inspections, detecting issues such as hot spots and panel defects with unprecedented accuracy. This proactive approach not only enhances operational efficiency but also minimizes downtime, ensuring continuous energy production. Additionally, AI-powered analytics facilitate predictive maintenance strategies, allowing for early intervention and prevention of potential failures before they impact system performance. Furthermore, the use of drones reduces safety risks associated with traditional manual inspections, while also minimizing environmental impact by optimizing resource usage. Ultimately, by combining AI and drone technology, solar plant operators can achieve cost savings, improve reliability, and support sustainable energy practices, making thermal drone inspection a vital tool in the ongoing maintenance and management of solar panel installations.

Are you ready to elevate your solar plant maintenance? Contact us for expert consultancy and take the first step towards a more efficient and reliable solar power system.